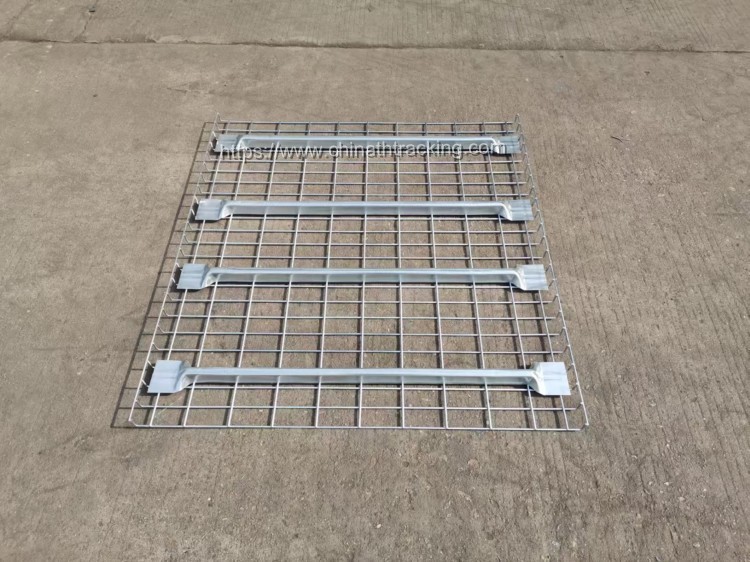

Galvanized Wire Decking

Steel wire mesh decking consists of wire decking and support reinforcement. One piece has a loading capacity varying from 300kg to 1000kg. It is suitable for storing boxed goods or loosen goods. Its sizes are customized.

China THT -Galvanized Wire Decking

Galvanized wire decking are mainly welding wire and reinforcing bar. The welding wire is an iron wire with a

diameter of 3-6mm.

The welding wire is connected together through spot welding or touch welding process. The diameter of

the welding wire itself

has changed, and the distance between the two welding wires will affect the bearing of grid laminate.

The reinforcing bar is a curved U-shaped iron bar, and the iron bars at both ends of American grid laminate

will not be flattened, Instead, a certain distance is reserved. For the conventional grid laminate, the iron bars

at both ends will be flattened, and the thickness and quantity will also affect the bearing. The stiffener will

generally be welded below the welding wire, which can play the role of support on the one hand and fixation

on the other.(1-Stiffeners,2-Welding wire),The following figure shows the American grid laminate.

The length of the stiffener is shorter than the depth of the mesh, so as to adapt to the steps of the American

stepped beam.

The raw materials of wire mesh decking are made of high-quality cold drawn wire spray welding to form a

mesh of 50*50 mesh. The reinforcement is reinforced at the bottom, and the two sides are bent and placed

on the shelf beam to ensure cargo safety. General load of up to 3T, surface treatment for galvanized and

spray processing. Generally based on heavy shelf size to produce the shelf layer network, according to

different bearing requirements, shelf layer network production style is also different, the general can

be summarized as follows: : 5.0, 6.0, 6.4 and 8.0; Mesh: 50*50, 50*100, 25*25, 50*25; Ribs:

Generally U-shaped steel with a length of 110mm is opened, and the ends are flattened.

ADVANTAGES

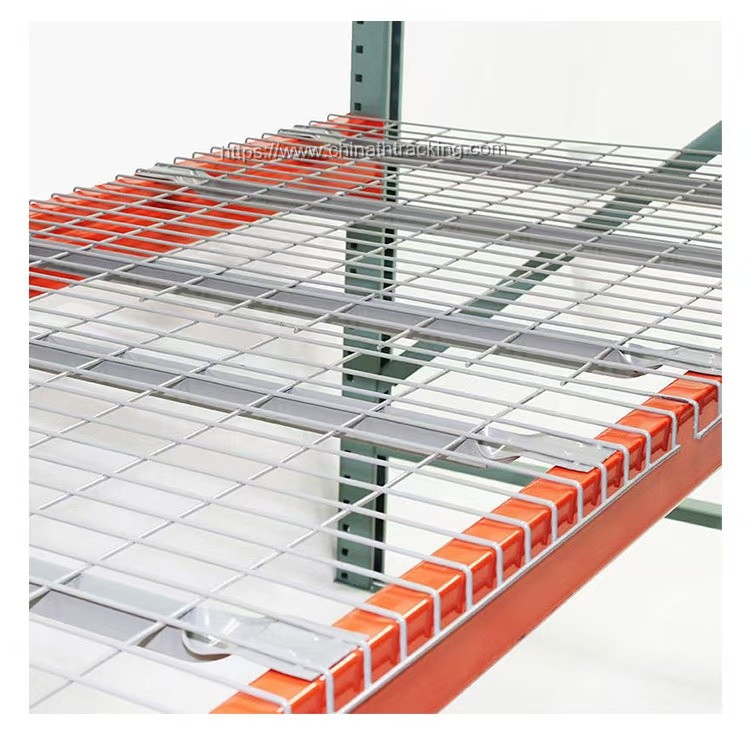

1.Visualization for easy management.

2.The grid-type laminate is firm, with strong bearing capacity, which is convenient for clean storage of bulk cargo.

3.The installation of network-type laminate does not need any tools, but can be directly placed between the beams.

4.Manual storage, no need for tray storage

5.The laminated screen design prevents objects from falling from the sky.

6.The installation of network-based laminates can make the size of the tray diversified on the shelf.

7.Stronger and safer than wood .

8.Custom designs available

9.Prevents product from falling off shelf level.

10.Better organization for FIFO — first in, first out — and picking planning

Packing

INQUIRY

CATEGORIES

LATEST NEWS

-

Show you our new pallet rack proje

Pallet racks are an integral part of most modern

-

Show you our new project -Radio Sh

HIGH DENSITY RADIO SHUTTLE RACK Radio shuttle

-

Show you our Galvanized Frame Pall

Show you our Galvanized Frame Pallet Rack

CONTACT US

Contact: Helen Jiang

Phone: 13552812790

Tel: 86-13552812790

Email: thtracking@126.com

Add: A BUILDING ,BULE SEA TRADE CITY ,TIANMU TOWN ,BEICHEN DISTRICT ,TIANJIN CITY,CHINA